Classification of Transducer and Selection Criteria of Transducer

In this article we will learn about the Classification of transducer and selection criterria of transducer. We will also discuss about the Application of Transducer.From this article we also discuss in detail about the thermister and RTD Advantages and disadvantages.

Classification of Transducer and Selection Criteria of Transducer

As per article we will discuss about classification of transducer and selection criteria of transducer.

Introduction of Transducer Classification

In general, a transducer may be defined as a device that converts one form of energy as shown in fig. Most transducers convert a non electrical physical quantity (such as displacement,force , temperature, light etc.) to an electrical voltage or current proportional to the magnitude of the physical quantity being measured.In an electric instrumentation system, the functions of a transducer (being the input device) are divided into two types:

Classification of Transducer and Selection Criteria of Transducer

Transducer may be classified in a number of ways on the basis of energy conversion,applications and on nature of outputsignal.

A sharp distinction among various types of transducers is difficult because a transducer may fall into more than one category and usually results in overlapping area of classification. It is describe of classification of transducer and selection critera of transducer.

Transducer classification

One the basis of energy conversion

- Passive Transducer

- Active Transducer

Passive Transducer

Passive transducer are also classified in different type . Which is provide help to understand of classification of transducer and selection criteria of transducer .

- Resistive Transducer

- Inductive Transducer

- Capacitive Transducer

-

Active Transducer

- Thermoelectric Transducer

- Piezoelectric Transducer

- Photo Electric Transducer

Classification based on Energy Conversion

-

Passive Transducers

Passive transducers are those transducers which require an external power for energy conversion.these are also called as ‘Externally powered Transducers’. The output of these transducers is a measure of some variation in a physical parameter such as resistance,inductance, capacitance etc. Examples of such transducers are resistive transducers, inductive transducer, capacitive transducers etc.

-

Active Transducers

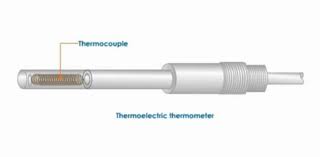

Active transducers are those transducers which develop their output in either one form-voltage or current without any external power source. Therefore,these are also known as self-generatigtransducers. However, they provide an electrical output when stimulated by some physical form of energy. For example,Thermocouple, photo voltaic cell etc.

Transducer Classification based on Applications

It is also a type of transducer classification which is provede help to understand about classification of transducer and selection criteria of transducer.

-

Primary Transducers

Primary transducers are those transducers which directly sense the input signal and convert it into an electrical form. Example-thermistors etc.

-

Secondary Transducers

When the input signal is first sensed first by some detector or sensor and then its output, being of some form other than input signal is given as input to a transducer Such transducer falls in the category of secondary transducers.

For example,pressure cannot be directly measured by a transducer. It is first coverted int displacement and then the displacement is converted into an out put voltage by an LVDT In this case,LVDT is a secondary transducer.

Classification on the Basis of Nature of Output Signal

This is also a type of classifiction which is prove help to understand of our title classifiication of transducer and selection criteria of transducer.

-

Analog Transducers

Analog transducers are those transducers which convert input signal into analog form which is a continuous function of time. For example,strain Gauge, Thermocouple etc.

-

Digital Transducers

Digital Transducers are those transducers which provide discrete output in the form of pulses for a given input. Sometimes when a analog transducer is combined with an alnalog to digital converter (ADC), it is called a ‘Digital Transducer.

Selection Criteria of Transducer

Now we are going to discuss about the classification of transducer and selection criteria of transducer.

Selection of the appropriate transducer is the first and fore most important step in obtaining accurate results. Following factors should be seriously considered while selecting transducer:

-

Operating Range

The operating range should be large enough to encompass all the expected magnitudes of measured.

-

Sensitivity of Transducer

It should be high enough so as to give a sufficient output signal per unit of measured input.

-

Frequency Response

It should be smooth (flat) over the entire desired range.

-

Physical Environment For Transducer

The transducer should be able to work at different environment conditions such as moisture,temperature,shock,vibration,pressure etc.

-

Error of Transducer

These should be small and controllable

-

Ruggedness of Transducer

A transducer should be rugged enough to withstand overload.

-

Reliability and Stability of Transducer

Reliability should be high so that minimum errors are encountered in measurement due to temperature variations, vibrations and other various changes in surroundings. The transducer should be stable. it should repeat the results without error. It is classification of transducer and selection criteria of transducer.

Resistive Transducers Working

Resistive transducers are those transducers which sense a change in the environment to cause a change in resistance.Environmental changes may be in terms of displacement, force,pressure temperature etc.

Strain Gauges Working

A strain gauge is a passive transducer which works on the principle of measurement of the change in resistance that is directly proportional to the strain applied.

In other words, it utilizes resistance variation of a wire to sense the strain (elongation/compression per unit length) produced by the force acting on the wire. It is extensively utilized for measuring weight, pressure, mechanical force displacement etc. It is alos provide advantage to understand about classification of transducer and selection criteria of transducer.

Resistance temperature Detctor (RTD)

Resistance thermometer or resistance temperature detector (RTD) are based on the principle of change in resistance of a conductor when its temperature changes. This resistance of a conductor when its temperature changes. This property is utilized for the measurement of temperature. RTD’shae positive temperature coefficient of resistance meaning their resistance increase with increase in temperature.

Advantage of RTD’s ( Resistence temperature detector)

- Fast response

- High degree of accuracy

- It can be installed and replaced easily.

- No necessity of temperature compensation.

- Best suited for remote indications.

Disadvantages of RTD’s ( Resistence temperature detector)

- Stability requirement limits the temperature range over which the sensing element may be used.

- High Cost

- Posibility of self heating

- External dc power supply is required

Applications RTD

- In heating ovens

- Compression mouldings

- Steam and Power Condensate

Thermistors Working and Advantages

Thermistors are those resistor which are sensitive to thermal/temperature variations. This property of thermistor makes it suitable to act as a transducer. It converts temperature changes in terms of resistance. It is also descrie of title which is classification of transducer and selectio critera of transducer.

Advantages of Thermistors

- Compact,rugged and inexpensive.

- Good stability in the negative temperature coeffient (NTC) region.

- Fast response over narrow temperature range.

- Cold junction compensation not required.

- Can be connected in series-parallel arrangement for increased power handling capacity.

Disadvantages of Thermistors

- Non linearity in resistance vs temperature characterstic.

- Unsuitable for wide temperature range. It can worki only with limited temperature range.

- Need shielded power lines.

Applications of Thermistors

- Measurement of temperature.

- Measurement of thermal conductivity.

- Measurement of power at high frequencies.

- Providing time delay.

- Measurement of composion of gasses.

- Measurement of flow level and pressure of liquids.

Inductive Transducers

In inductive transducers, the inductance of a coil or an inductor changes caused due to a corresponding change in the input quantity. This change in inductance is responsible for producing a change in output voltage

Inductive transducers may be either of active or passive type and work upon one of the following principles.

- Variation of self inductance

- Vriation of mutual inductance

Inductive transducer are mainly used for measurement of displacement which produces variation in any one of the threevariables.

- Number of turns of the coil.

- Geometric configuration

- Permeability of the magnetic material o magnetic circuits.

- Linear Variable Differential Transformer (LVDT)

It is a passive inductive transducer (or magnetic displacement transducer). It is commonly employed to measure force (or weight,pressure and acceleration etc.Which depend on force) in terms of the amount and direction on displacement of an object.

Hence these are classification of transducer and selection criteria of transducer. We have also studied about the different types of transducer and advantage and application of thermister.wokring and application of RTD (Resistence temperture detector).